Feb 1, 2021 · Introduction. Industrial fermentation utilizes microorganisms to produce various products, including antibiotics [1], organic acids [2], pharmaceutical proteins [3], and industrial enzymes [4], etc. It is estimated that the biotechnology products cover one-third of the worldwide market, with a value of more than 300 million USD [5].

Nov 1, 2020 · In this paper, an intelligent and automatic fungi fe rmentation cultivation system is designed to monitor. the situation of fungi fermentation in real time, compare and analyze the data in the

An optimized small-scale process can then be transferred to pilot scale following established scale-up strategies. The basics of successful fermentation scale-up start with proportional fermentor and impeller design. Eppendorf fermentation systems were designed following bioprocess industry stirred-tank design standards and provide excellent

Nov 1, 2020 · There are two challenges that must be overcome in designing small-scale fermentation tests to study heterogeneity effects: (1) how to design small-scale fermentation equipment to reproduce mixing conditions at large scale and (2) quantifying the degree of heterogeneity that is experienced by a given fermentation process in a large vessel.

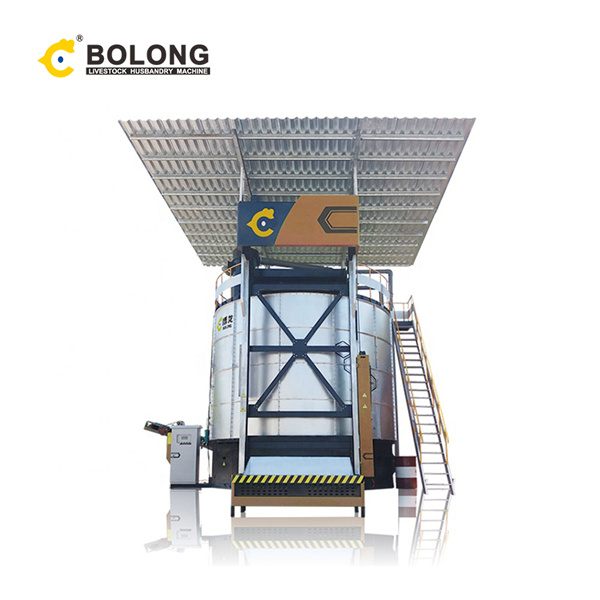

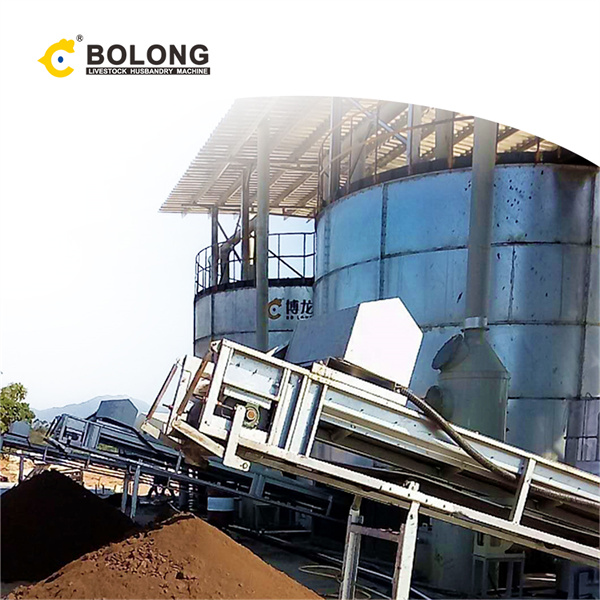

Nov 12, 2021 · Traditional chicken manure fermentation is mostly natural composting or exposure, which is not only time consuming but also susceptible to weather, resulting in uncontrollable quality and environmental pollution. This research aims to build a smart solar chicken manure fermentation system to control the conditions of chicken manure fermentation effectively, improve quality, and solve the

Aug 3, 2023 · Design of a Fermenter. Construction Material, Temperature Control, Agitator (Impeller), Stirrer glands and bearings, Baffles, The aeration system (sparger), pH control sensors.

Apr 1, 2024 · Please contact clientservices@accessintel.com or call 1-888-707-5814 if you are unable to login. (Page 1) With the growth of ‘white biotechnology,’ industrial fermentation processes and large-scale fermenters will play a key role. Presented here are some design considerations In fermentation, microorganisms With the growth of ‘white

The reliable operation of a fermentation system to achieve process objectives depends on two factors: the fermentor design and the fermentation process. The design should consider from the outset such factors as plant scheduling, space constraints,

Jul 12, 2021 · and. A. Ekblaw. Space Exploration Initiative at Massachusetts Institute of Technology, 75 Amherst St, Cambridge, MA 02139, USA. Food preservation and waste management are challenges that concern

In this application note, the team used E. coli fermentation to demonstrate the scale-up capabilities of Eppendorf fermentation systems from small scale to bench scale and pilot scale.

The design and implementation of the microorganism fermentation monitoring system proposed in this paper, based on the embedded system as the core, combined with sensor technology, and used the King-View software platform to develop the upper computer monitoring interface. It can measure the parameters in each fermentor timely and accurately

Fermentation system must be efficiently controlled in order to optimize productivity, product yield and ensure reproducibility. The key physical and chemical parameters involved largely depend on the bioreactor, its mode of operation and the microorganism being used.

Product Description. $199.99. The Catalyst Fermentation System (6.5 Gallons) is an innovative piece of homebrewing equipment that simplifies the fermentation process, making it easier than ever to make great beer at home. We've taken features seen only in high-end, professional brewing equipment and integrated them into a compact homebrewing

In an operating fermentation system the following balance equation can be given by: 1 d (Vy ) = V dt ∑r gen − ∑ rcons + Dyi − γDy0 (26) where, y is any state variable, Srgen means the sum of all generation rates, Srcons is the sum of all consumption rates, V is the bioreactor operating volume, F is the flow rate, D is the dilution rate

Jan 1, 2014 · Figure 6.4 is a block flow diagram of a sterilizer that is suitable for fermenter volumes of 20,000 to 60,000 gallons capacity. It is based on pumping 150 gpm of non-sterile media to the steam injector. Energy savings could be about 45% if the hot water storage capacity (Tank 5) were equal in volume to a fermenter.