Mar 10, 2024 · To develop a mathematical model of pH control plant in the yeast fermentation process, the following two conditions should be assumed. ① The concentration of acid, alkali and buffer solution are constant. ② The materials in the fermentation tank are completely mixed and the ions in the solution are completely dissociated.

This compost releases nutrients slowly, ensuring a steady supply for crops and reducing the need for chemical fertilizers. Microbial Activity: Healthy soil is rich in beneficial microbes. The compost from fermentation tanks supports microbial activity, promoting a balanced soil ecosystem. This leads to improved soil fertility and plant health.

Feb 26, 2024 · Draining and Utilizing the Nutrient-Rich Tea. One of the critical steps in managing your Bokashi bin is the regular drainage of bokashi tea. This nutrient-rich liquid accumulates as the kitchen scraps undergo the fermentation process. Ideally, you should drain the liquid every 2-3 days to prevent buildup and ensure the system functions correctly.

Regardless of fermenter type, (1) the culture vessel, (2) input–output systems ports for nutrient media, gas, and product, and (3) control systems are common to all. Mixing is crucial for fermentation since it causes oxygen dispersion and homogenization of media.

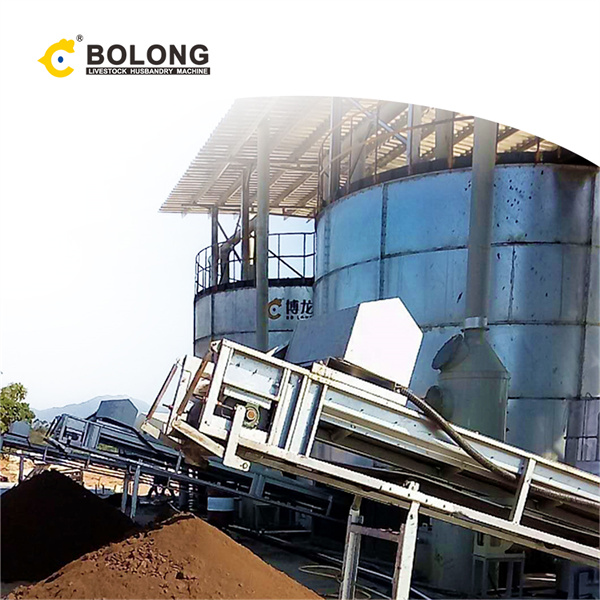

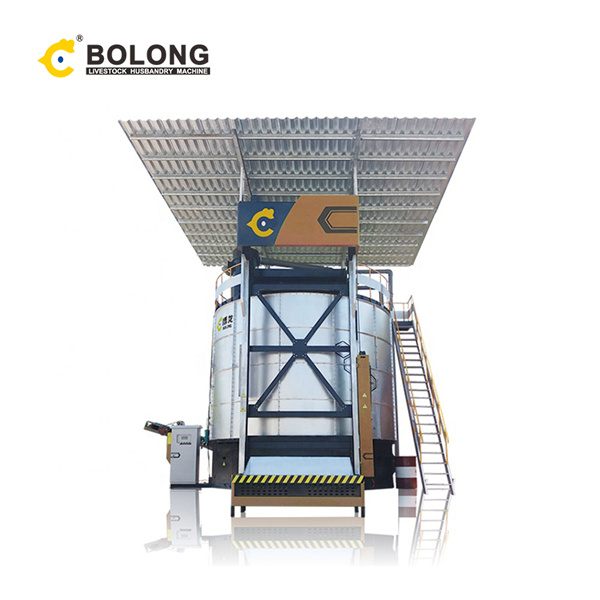

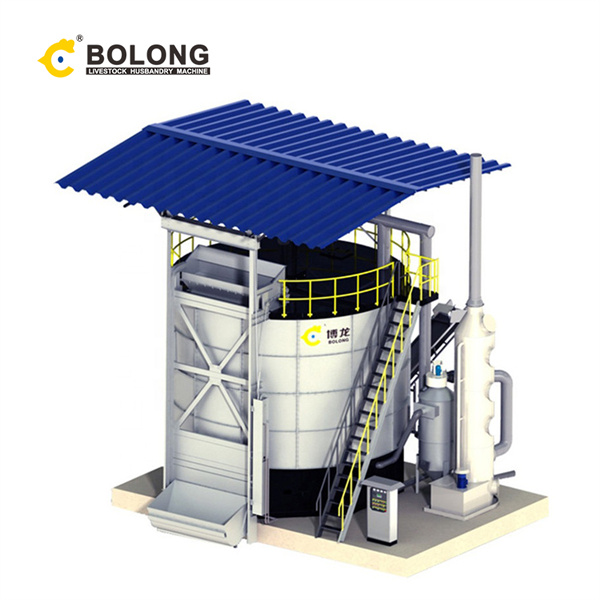

Vertical fermentation tank, also known as vertical composters or aerobic fermenters, are designed to promote the decomposition of organic matter into nutrient-rich compost under aerobic conditions. The principle of operation includes the following key steps: 1) Loading: Organic materials are loaded into the vertical tank.

Our fermentation tanks are designed to ensure precise temperature control, efficient yeast management, and consistent fermentation outcomes in every batch. 1. Precise Temperature Control: Prodeb Distillery Fermentation Tanks provide precise temperature control to create an ideal environment for yeast activity and flavor development.

Apr 6, 2018 · Introduction The goal of fermentation management is to develop a robust population of microorganisms that will complete the fermentation and resist any biotic or abiotic stress that may occur along the way in addition to the production of positive aromatic characters contributing to complexity. Grape juice is rich in nutrients, particularly in sugars from which energy will be derived.

Dec 1, 2020 · Biochar produced from nutrient-rich agricultural leftovers and waste streams has multiple environmental benefits and can be used as a soil amendment explicitly for organic crop production [3], [4]. It can significantly enhance soil fertility and crop yield while reducing greenhouse gas (GHG) emissions and leaching of nutrients, heavy metals

Dec 7, 2023 · Assess Nutrient Requirements: Determine the specific nutrients essential for maintaining proper nutrient control during the fermentation process, such as nitrogen, phosphorus, and trace elements. Monitor Nutrient Levels : Regularly measure and adjust the nutrient concentrations to maintain an optimal environment for the microorganisms and

Nov 16, 2023 · Efficiency and Output: Highlight the focus on efficiency and high output in these larger setups. Consistency and Quality Control: Discuss how larger tanks affect maintaining beer consistency and

Apr 16, 2024 · These tanks provide a controlled environment where yeast converts sugars into alcohol and carbon dioxide, giving beer its alcohol content and carbonation. The design and material of fermentation tanks are critical to this process, with most modern tanks being made from stainless steel for its durability, cleanliness, and non-reactive properties.

Jan 1, 2015 · Beer fermentation is traditionally done without the use of mechanical agitation. Mixing in CCVs is provided mainly by the CO 2 evolved plus a contribution from convection as a result of cooling (Takamoto & Saito, 2003). However, there is very little CO 2 evolution at the start of the batch or at the end when the nutrients become depleted. In

Angel Fermentation Nutrients, rich in protein, amino acids, peptides, nucleotides, B vitamins, and trace elements. With the advantages of having no allergic source and being non-transgenic, high efficiency, and stable quality, Angel YE are widely applied in biological laboratories and industrial-scale fermentation, promoting product safety and technical progress in the global fermentation

Fermentation kinetics, i.e., the rate of sugar consumption and ethanol or CO 2 production, depend on interactions between yeasts, the availability of nutrients in the must and parameters controlling fermentation (e.g., temperature). Optimizing the control of alcoholic fermentation for winemaking is a difficult challenge.

Jan 19, 2024 · Beer fermentation tanks cover a wide range of sizes from a few barrels to massive volumes over 1000 barrels. Some typical fermenter capacities include: Pilot Systems: 1-3 BBL. Microbreweries: 3-7 BBL, 7-30 BBL. Pub Breweries: 15-30 BBL. Production Breweries: 30-300 BBL, 600-800 BBL, 1000+ BBL.